The printing process is safe, and it is not a problem to run these printers at home or in an ordinary office. The material is sold as a filament, a plastic fiber of one color wrapped on a spool, and that is why the finished objects are usually only monochromatic. This disadvantage can also be avoided for example, by using multiple nozzles each of which prints a different color, or if the model of the printed object is adjusted appropriately to print in a different layer with different colors. The use of the 3d printing powder comes important there.

Using 3D printing

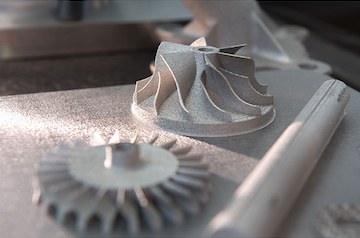

3D printing has many applications at present. It is most often used for production of prototypes, various components, and unconventional shapes or for production of otherwise very expensive components. In the future, however, 3D printers could be used to produce almost anything. Nowadays it is possible to print e.g. metals, precious stones, ceramics, wood, houses, weapons, food or even human tissues.

Examples of use

- Product prototypes

- Parts for aircraft, cars and the like

- Arms

- Artificial joints, prostheses, bone replacements

- Complete construction of the house

- Jewelry and fashion accessories

- Components for other 3D printers

- Food

- Clothes

- Household Goods

Simply put, printing goes almost anything. However, only plastic printers are currently affordable for the general user.

Types of printers

There are two most common types of printing FDM and stereo-lithography. The most used is FDM or fusing deposition modeling.

FDM

FDM is a method where an object is created layer by layer by melting a thin strip of plastic material. The material is melted most often at a temperature of about 200C depending on the material. Printed objects have visible layers, and print quality depends on the specific printer, material, printer speed setting, and layer thickness.

Stereo-lithography

Inkjet printing, which laid the foundation for the 3D printing technology was invented already in 1976. 3D printing itself was founded in 1984, when it was first patented technology of stereo-lithography later founder of 3D Systems Charles W. Hull.

The models produced by this method are extremely smooth and high resolution. Printing is faster than FDM, but printers are more expensive as well as material resin. This printer selection article will primarily focus on the FDM method because it is the most widespread, popular, and available to general users.

Classification by coordinate system

There are two main variants: Cartesian and delta. Others used are Polar and Scara.

Cartesian

The classic layout as in a traditional or laser printer on the X, Y, and Z axes thus moves the printer head up and down, and the pad moves back and forth. This makes it possible to print smaller objects up to the height of the printer.

Delta

Delta printers also use the X, Y, Z axes, but the extruder is hinged on 3 arms so the printer can print mainly tall and narrow models. This printer was designed to print faster. These printers are also slightly more expensive than conventional printers.

Polar

3D printers built on the polar system use two axes to move the print head and the rotary washer. This system is easier to build, but worse to control, and there are not too many slicers that can convert into curves. Curve extrusion has certain advantages for printing certain models, especially the vase type. Technology is very young.